Super Simple DIY No-Sew Shirt Repair

Super Simple Shirt Repair

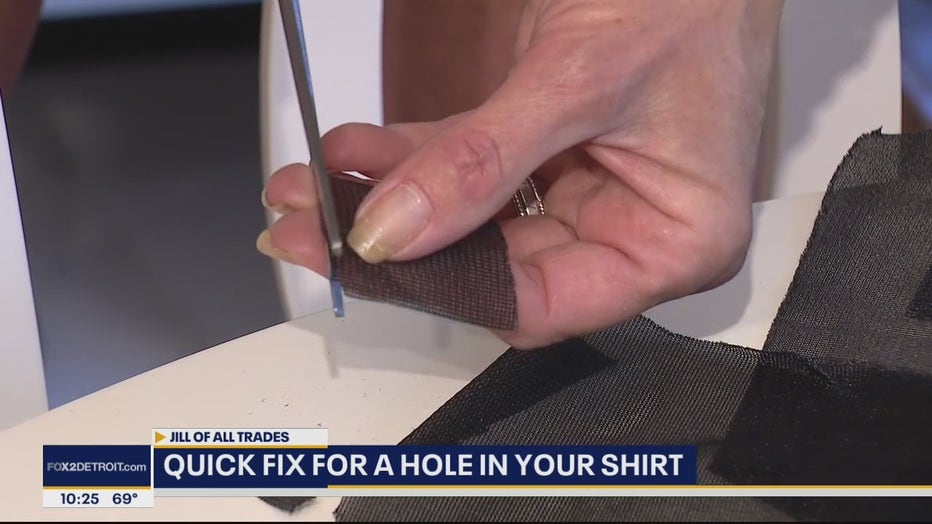

Jill of All Trades shows us a super easy way to repair a torn shirt, and it only takes a couple minutes!

This week, Jill Washburn, our Jill of All Trades, shows us the easiest way in the world to repair a shirt that some people might consider ruined. It all started with a brand new polo shirt that came from the store with a little slice in it. The problem was, it got worn before the slice was noticed, so it couldn’t be returned. Now what? Nobody wants to wear a shirt with a tear in it.

This new polo had a small slice in the fabric.

Jill of All Trades to the rescue!! Jill figured she had the perfect solution for repairing the shirt and she was betting that it was going to be easy.

Jill says that she was lucky, because none of the shirt’s fabric was missing, it was only sliced. She could lay the shirt out on a table and push the sides of the slice together and it looked good. The challenge was to keep it like that permanently. Jill decided to bond a fusible facing to the inside of the shirt, to hold the slice together.

I used a super sheer lightweight fusible facing.

Because the shirt was a dark navy blue, she chose a black fusible facing. Make sure you use a fusible one, says Jill, because you want one that you can iron on, instead of sewing. She had a handful of options to choose from at the fabric store. Because the polo shirt was a "tech" fabric with kind of a silky finish, she opted for a super lightweight knit fusible facing. It was very drape-y and had a mesh-like appearance to it. It was so sheer that Jill figured the repair would not be detectable from the front of the shirt.

Jill laid the shirt out, inside out, on her ironing board. She cut a small square of the facing that would easily cover the sliced spot. Jill applied the facing, adhesive side down, on the spot to be repaired. You’ll know the adhesive side, says Jill, by the tiny dots on one side of the fabric. That is the adhesive that will bond the facing to the fabric when you apply heat.

Super Simple Shirt Repair

Jill of All Trades shows us a super easy way to repair a torn shirt, and it only takes a couple minutes!

Once it was all laid out, Jill made sure that the slice was closed up and the facing was where it should be. It was time to apply some heat. Jill used her iron on a low setting. For extra precaution, she also used a pillowcase on top of it all to help moderate the heat. Because the shirt was a tech fabric, Jill was afraid of using too much heat and melting the repair spot. The combination of the low heat setting and the pillowcase was perfect. It gave her enough heat to fuse the fabrics without damaging the shirt.

Jill took her time, going over the facing a few times, to make sure it was truly bonded in place. Even at that, it only took a minute or two to get the facing fused into place and complete the repair.

Voila! Done! The shirt is repaired and back in service! You would have to look super close to find the repair and, even then, you’d have a tough time detecting it. A pricey shirt was saved with less than a dollar’s worth of facing and a few minutes of time. And, it was so easy!

PROJECT RATING: Super Easy

To watch Jill take you through the process, just click on the video player above.